How we work

Sarginsons’ methodology revolves around the Sarginsons Technology Centre, which fuses cutting edge research with the wider commercial environment in which our products have to deliver value. using this methodology, we have proven that we can solve all diecasting problems by engaging our consultancy division at the earliest possible stage.

The Sarginsons Technology Centre ensures that our Design for Manufacturing capability is the best in the industry and that every project we deliver is scoped and executed to maximise the commercial benefit for our clients. Our process ensures that product quality and cost effectiveness are optimised at all times.

When we say, therefore, that we lighten your load, we are not simply referring to the benefits of our low pressure diecasting. We also lighten the operational and financial load that complex manufacturing processes can place on businesses. Our process has six components:

Scoping

Engagement with the Sarginsons Technology Centre at the Scoping Phase is the foundation of optimal product development and delivery. The main function of this phase is to ensure that the project we have been commissioned to deliver is able to link the Voice of the Customer (VOC) to diecasting technology, production knowledge and design. This enables us to dramatically cut component development times and costs.

Knowledge Transfer

Sarginsons is different in approach and effectiveness because we focus on knowledge as the foundation of all new projects. To this end we are partners in every major research project into metal casting technology in the UK and have invested over £10m in Research and Development over the past six years. Thanks to work with research centres such as BCAST, AMPC and AMCC we are acknowledged thought leaders on all casting and metal processing techniques. This knowledge gives our clients a tangible market advantage. For example, as lead partners in LEAAST, a research programme conducted alongside Jaguar and Brunel University, we developed the BD1 aluminium alloy, which provides new levels of ductility, whilst also being recyclable.

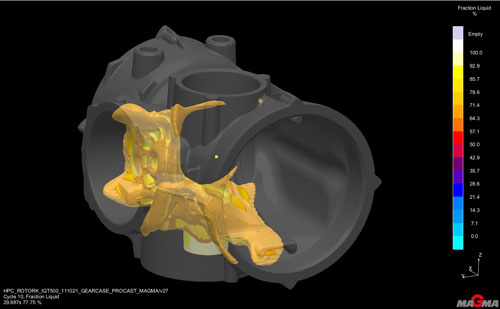

Simulation

The application of MagmaSoft Casting Simulation Software is at the very heart of what we do. It ensures our casting simulation expertise combines the latest software with all our production data to provide a real time projection of what works when theory meets reality.

Simulating castings based on evidence from thousands of actual castings is the quickest and cheapest way to determine the optimum casting solution in terms of method, practice and materials. Our engineering teams expedite the efficacy of this process by auditing all designs prior to any simulation launch.

Technical Project Management

The best design and engineering is only as good as the process for translating expertise into real-world effects, which is why we are leaders in the deployment of project and process management technologies. This is what guarantees on time delivery of projects, components and required quality standards.

The Advanced Product Quality Planning (APQP) process forms the base of our technical project management which we operate from design through production. It is the ultimate proof of product worthiness as it ensures that all the technical, dimensional, metallurgical and fitness-for-purpose requirements of the product are met and that barriers to efficient and effective supply are eliminated.

Metrology and Process Monitoring

At every stage, from the first scoping meeting through to design, production and delivery, data is the key to success.

Data driven decisions are based on legendary beliefs – If You Can’t Measure It, You Can’t Improve It. Continuous measurement techniques are utilised from liquid metallurgical studies through to final metrology based reporting.

Sarginsons culture of continuous improvement and teamwork emulates from our quality ethos and extends through to all business processes.

Our Business Operating Procedures define functional responsibilities ensuring customer specifications, standards and expectations are fully delivered.

An Ethos of Continuous Improvement

Sarginsons Technology Consulting is the best in the diecasting industry because of the people who drive it and the processes they work to. Sarginsons is home to world leading experts in every aspect of Low Pressure Diecasting, Gravity Diecasting, Sandcasting and Finishing and Assembly. Their diligence and dedication combined with robust and proven processes is what makes Sarginsons one of the UK’s leading design and manufacturing businesses. That we are continuously improving is both a benchmark for our competitors and a promise to our clients.

Whitepaper: How to Design for Manufacture in Lightweighting

>>> Click here to download our latest whitepaper on How to design for Manufacture in Lightweigthing.