Right first time and Design for Manufacture are expressions trotted out with the best of intentions but, often in the casting world, with little actual method, planning or application. Yet, as the potential to improve every aspect of a component and customer satisfaction is probably greater in casting than any other field.

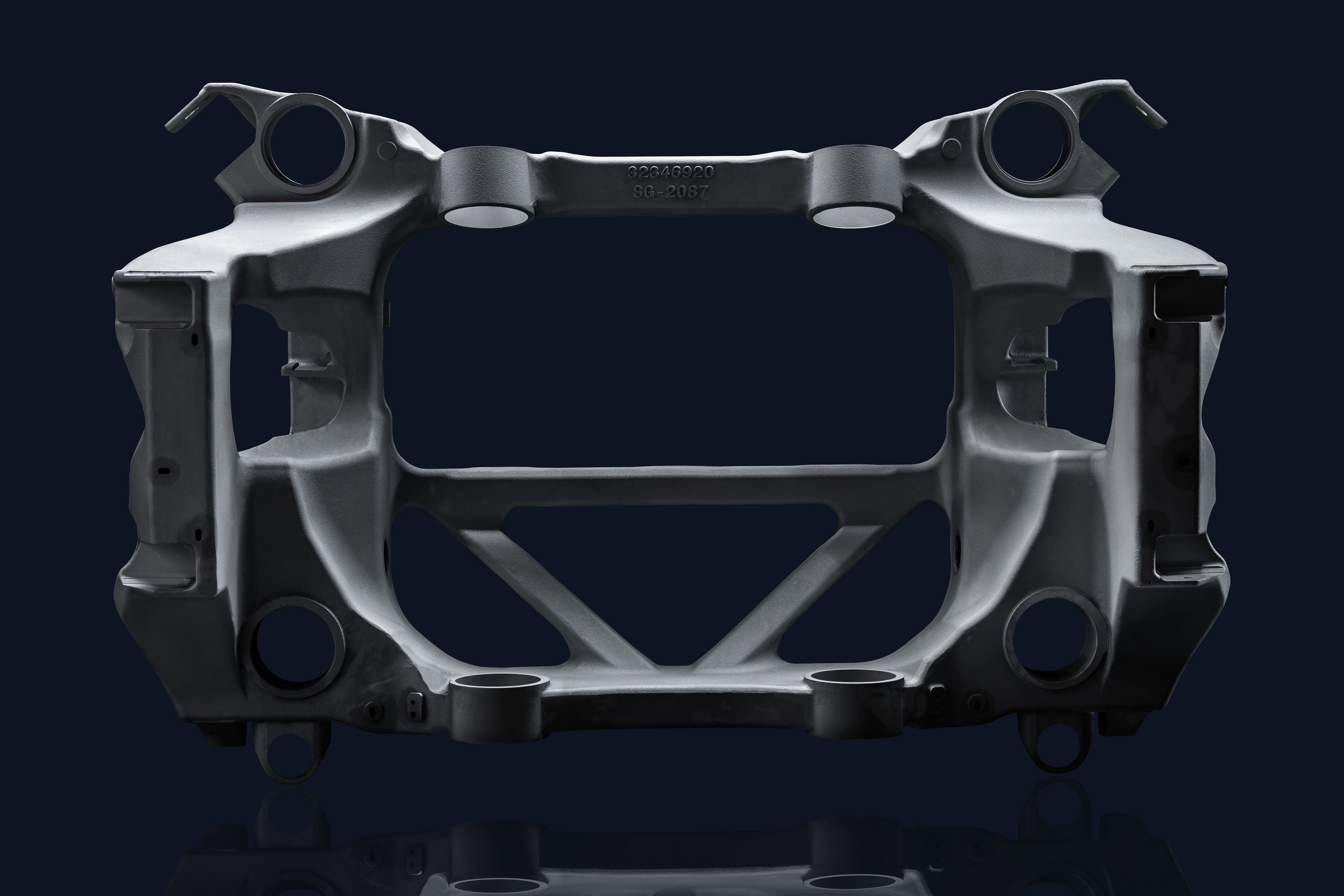

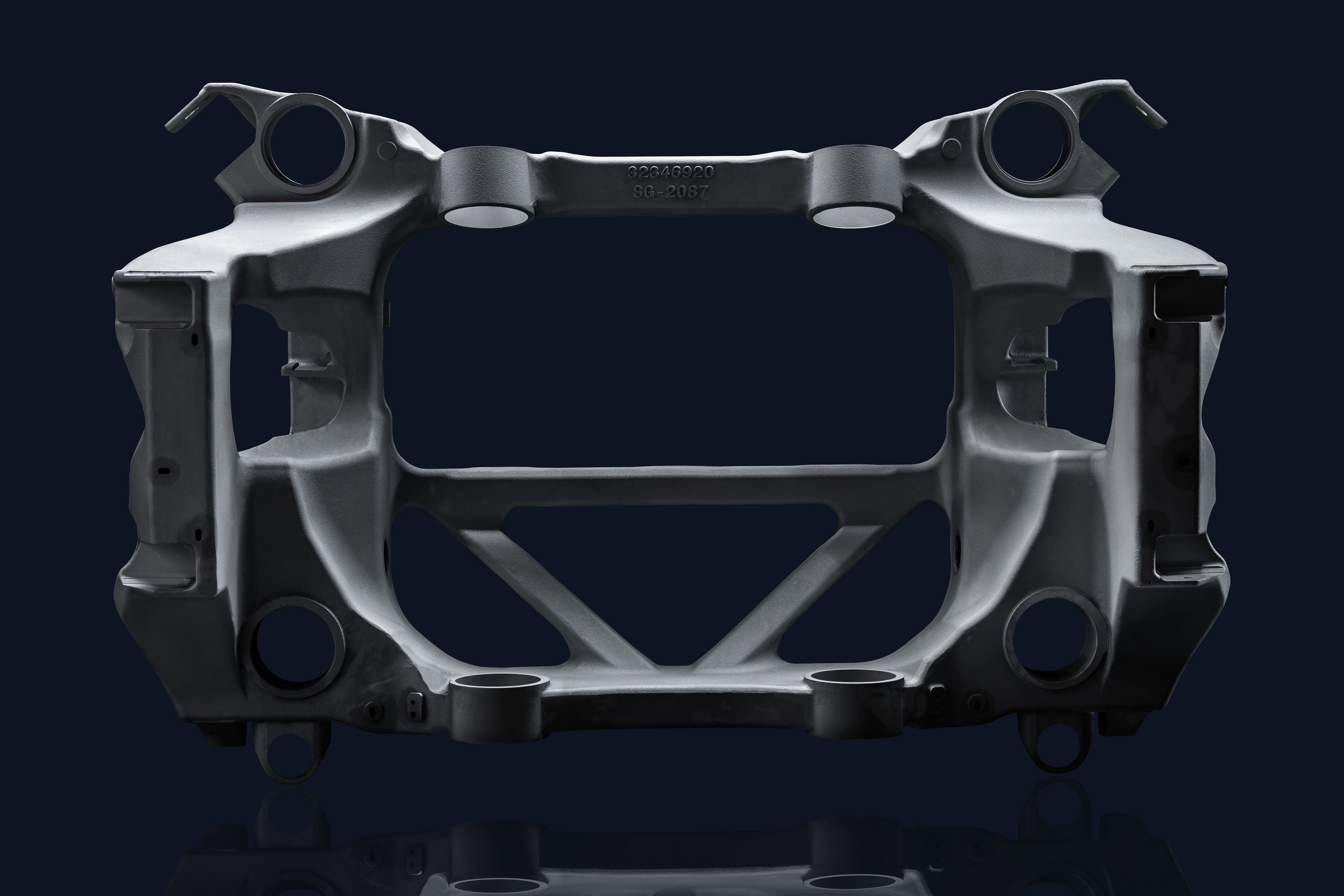

Casting is the most complex of all manufacturing technologies with any number of unpredictable variables. This forces designers to play safe and avoid the additional demands that full DfM and lightweighting create. Sarginsons has solved this conundrum by developing digital twin simulations that predict, for the first time, the variables that restrict cast component design.

For the first time designers can really start to implement full design for manufacture disciplines and push the boundaries of design for better mass and cost performance. Sarginsons has printed a guide to help those designers exploit this opportunity properly.

It is Sarginsons unique ability to use digital twin simulations to precisely simulate the mechanical performance of a casting that enables their lightweighting and DfM studies to be that much more comprehensive. They can incorporate any number of secondary operations, design requirements and good casting practice into the digital twin and make sure the whole package works mechanically.

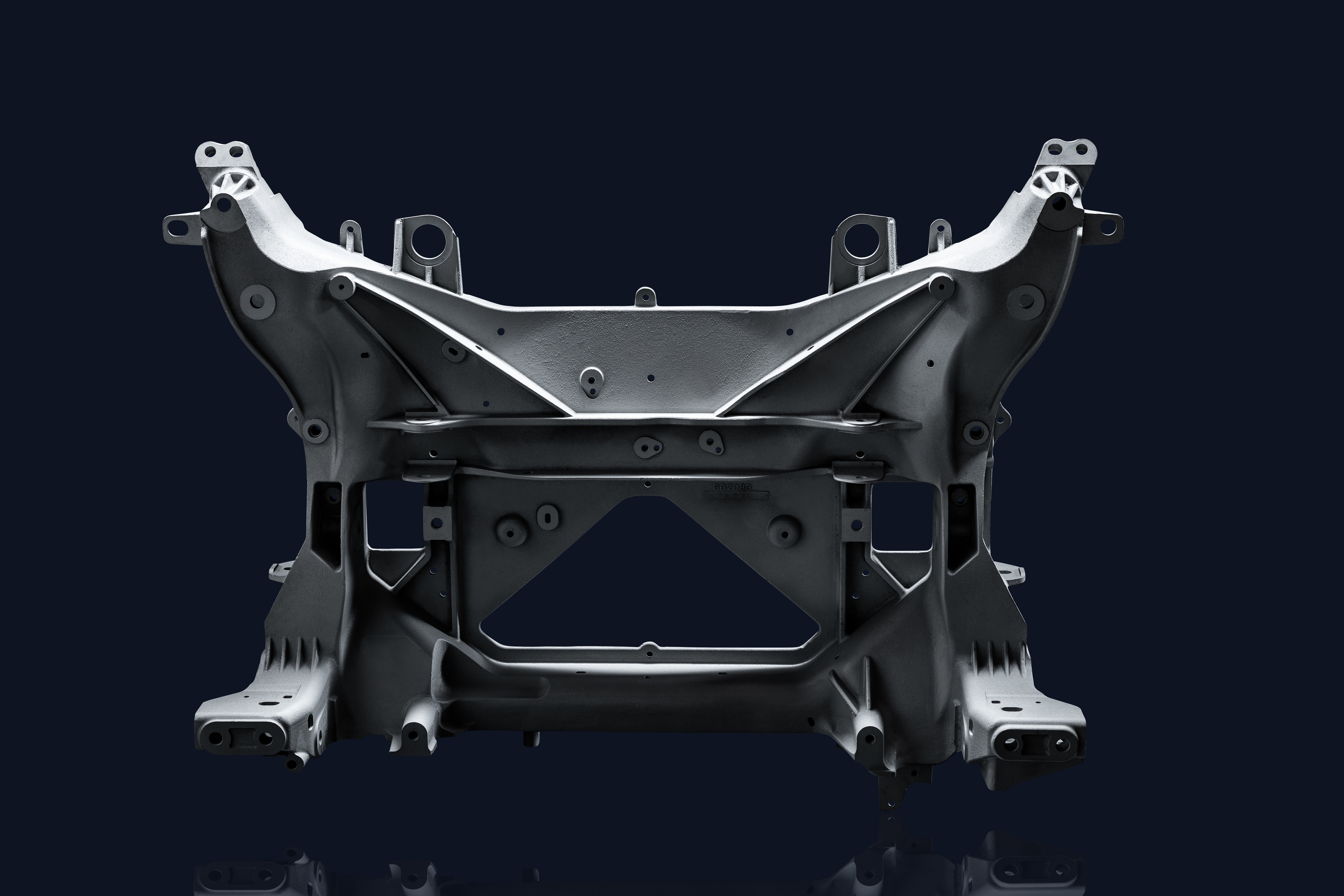

By also applying Topological Optimisation, the maths of lightweighting, to the mix we can maximise mass reduction whilst still using the digital twins to ensure mechanically viability. Sarginsons effectively combines the very latest in technology with the very best in casting practice and good product design. And the results are remarkable, with 30% weight savings and the reduction of multiple components to one.

Design for Manufacture is good practice. You make that anything that could make castings awkward, unreliable or expensive is designed out of the casting. And this Sarginsons does, but it also takes this whole concept a lot, lot further. It tries to incorporate everything in the components whole manufacturing journey that could be problematic. Everything from Datum points, CNC pathways and heat treatment distortion to robotic handling and coating is thought through during initial design.

Sarginsons DfM actively looks to accommodate every single aspect of the entire casting and finishing processes from the very first step.

Torrington Avenue, Coventry,

West Midlands, CV4 9AG