DfM is well known as the secret sauce of cost downs and improved margins. It is rarely done well and almost never covers everything it should or could. And in aluminium casting these sins are probably worse than anywhere else.

The seemingly infinite design flexibility of casting gives it, as a manufacturing medium, far more scope to accommodate production nuances than other methodology. And yet the division between component design, done by OEMs, and casting production, by foundries, frequently means design strategies are not sufficiently joined up to take advantage.

Sarginsons is different. Whilst it proposes involvement at the concept stage, it also operates the most exhaustive 'scope of work' assessment, with the precise aim of nailing every aspect of a components manufacture. We believe no other foundry takes its DfM as far. And none have the advantage of Digital Twin Simulation.

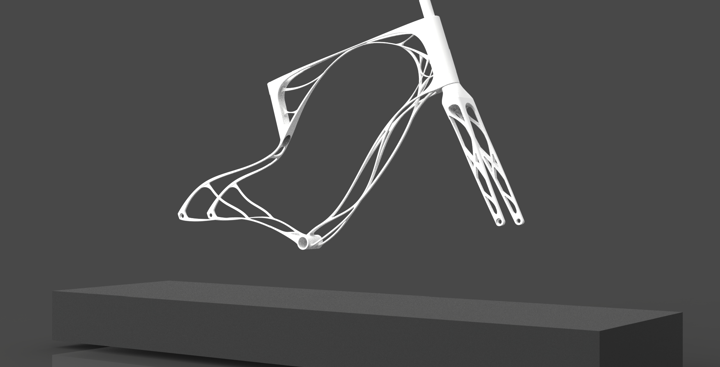

Sarginsons world leading digital twin simulations and topological optimisation for cast components is also effectively the world's only DfM simulation. It allows us to optimise the entire casting process by putting everything we want, from datums to fettling plans, onto a casting design and then ensuring it is light weighted and readily castable.

There'll be no surprises, no panicked redesign because the simulations make sure the casting designs are fit for purpose and the TYE mechanical performance, exactly what is required. This ability to simulate all aspects of performance is a huge advantage and can represent a serious cost reduction as well as improved peace of mind.

Ironically, it was the ability to use digital twin simulations to assist the DfM process, that highlighted all the other areas where DfM really played a role. It was integrating the heat treatment process into the DfM package that led directly to the concept of Designed Deformation, where a component is designed so that the distortion generated by heat treatment actually forces it into the correct alignment: surely no better example of extreme DfM exists than this.

It's not just about the use of digital twin simulations as there as so many mundane aspects of the casting and finishing process that can be accommodated - from CNC machining pathways through handling and fixturing, core design and heat treatment.

DfM is exceptionally important for viable, cost effective components.

Torrington Avenue, Coventry,

West Midlands, CV4 9AG