Exploit the Technology of Casting

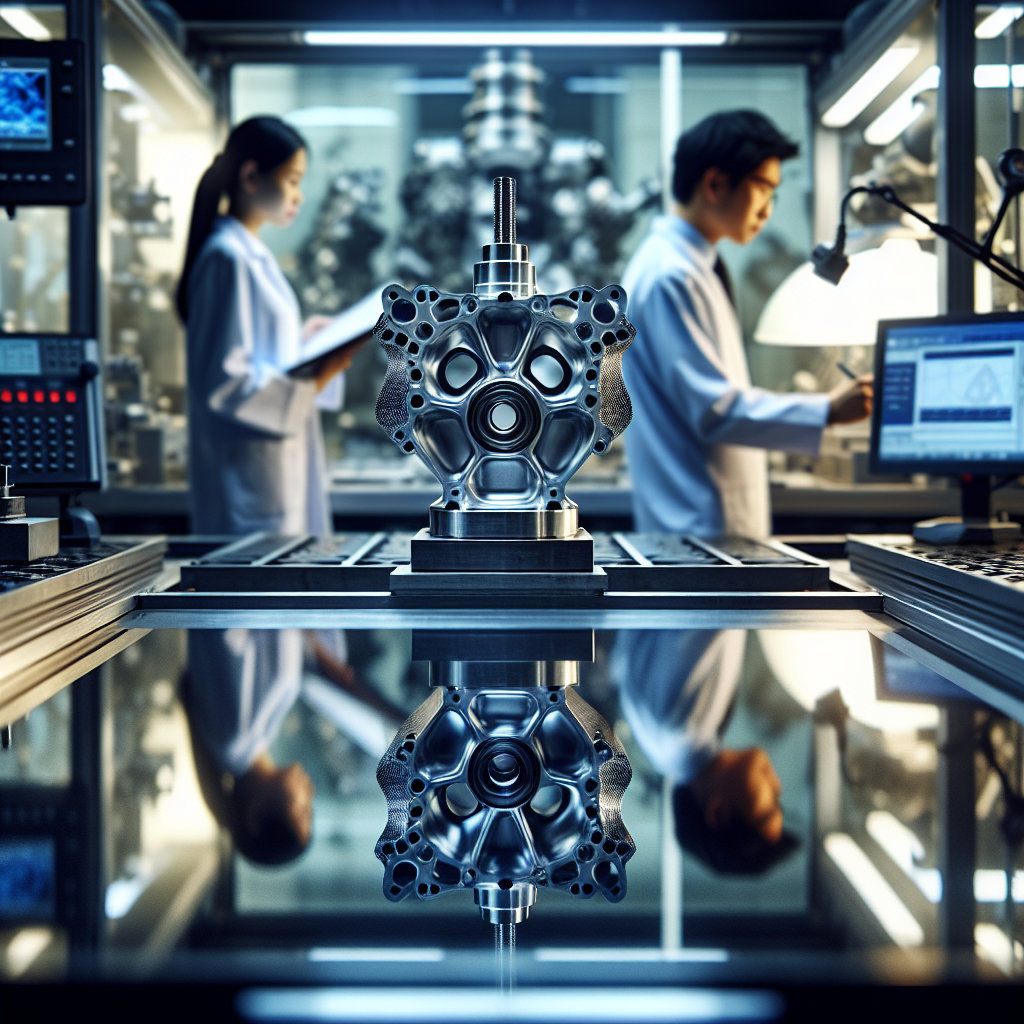

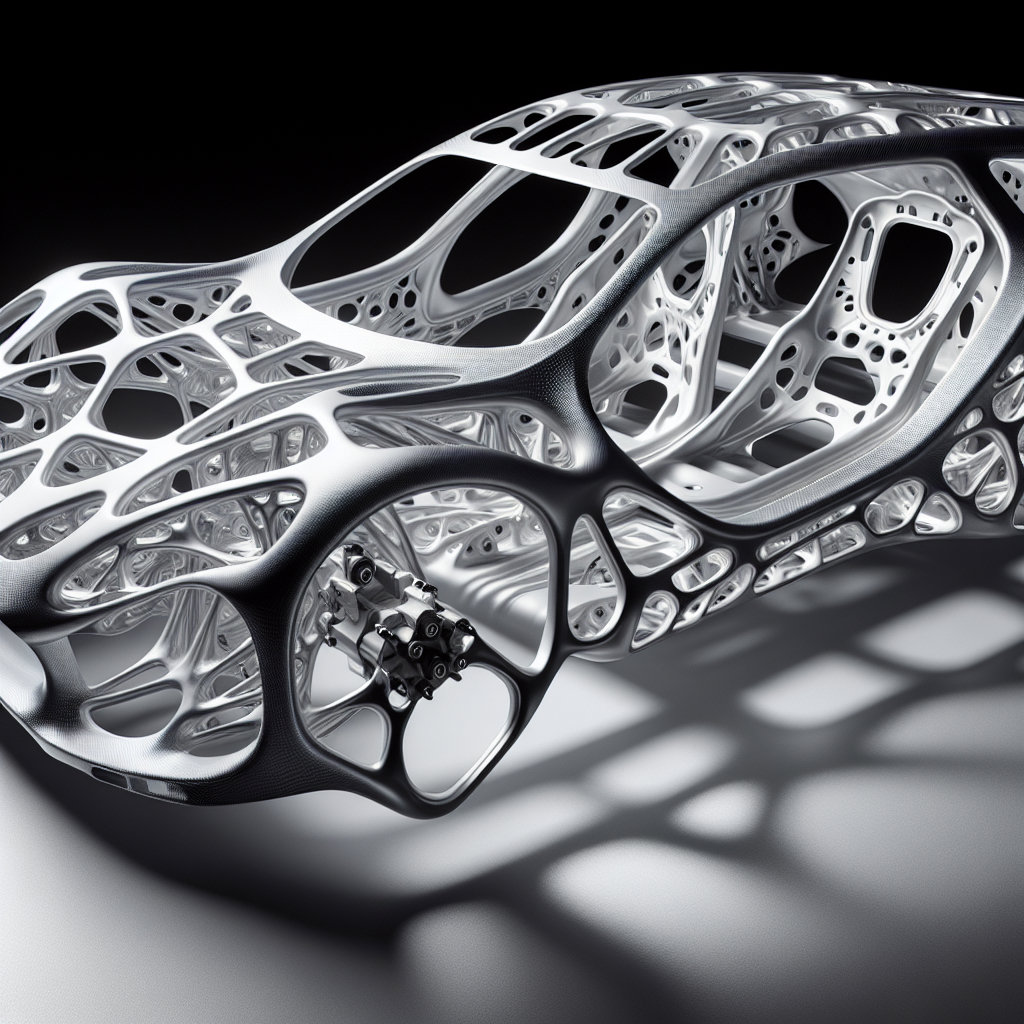

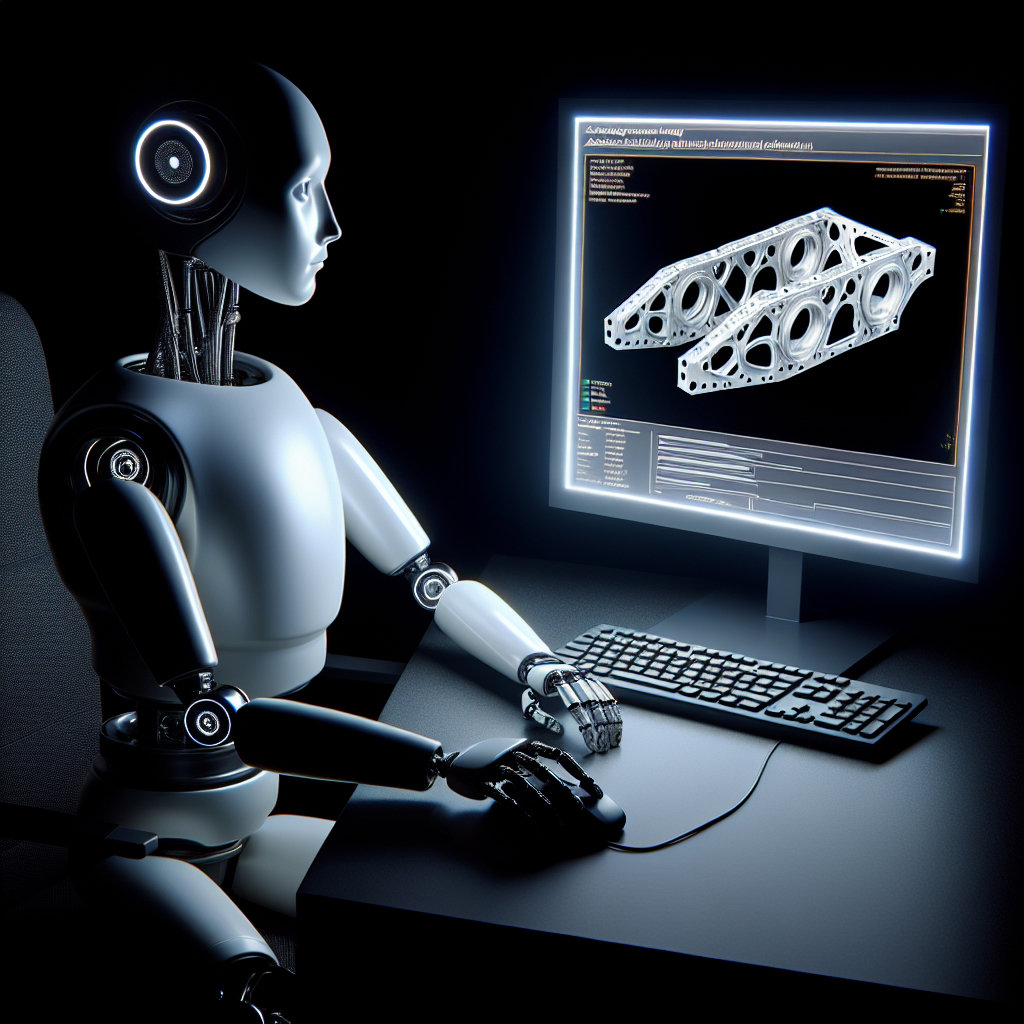

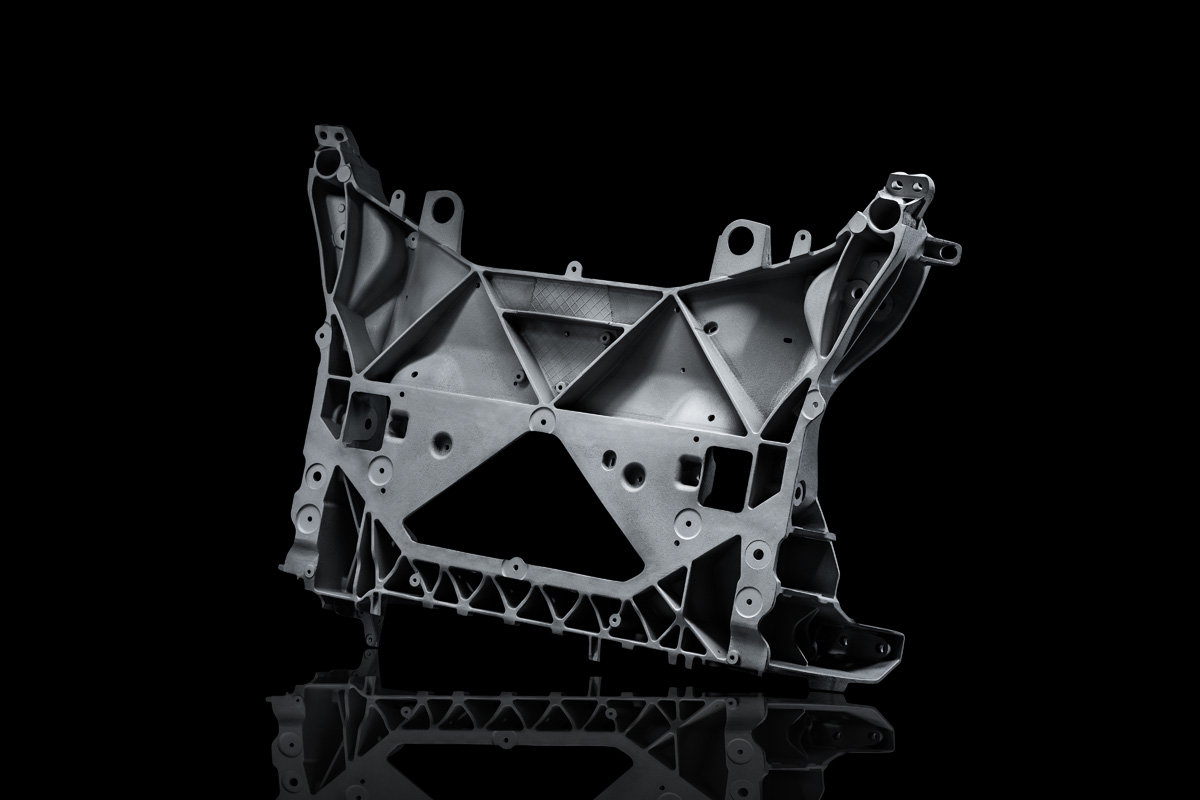

Sarginsons, an advanced aluminium foundry, leverages cutting-edge technology to conquer casting challenges by using technology to unlock the vast, untapped potential of liquid metal engineering. Creating unprecedented efficiencies and superior solutions, which must not be ignored.

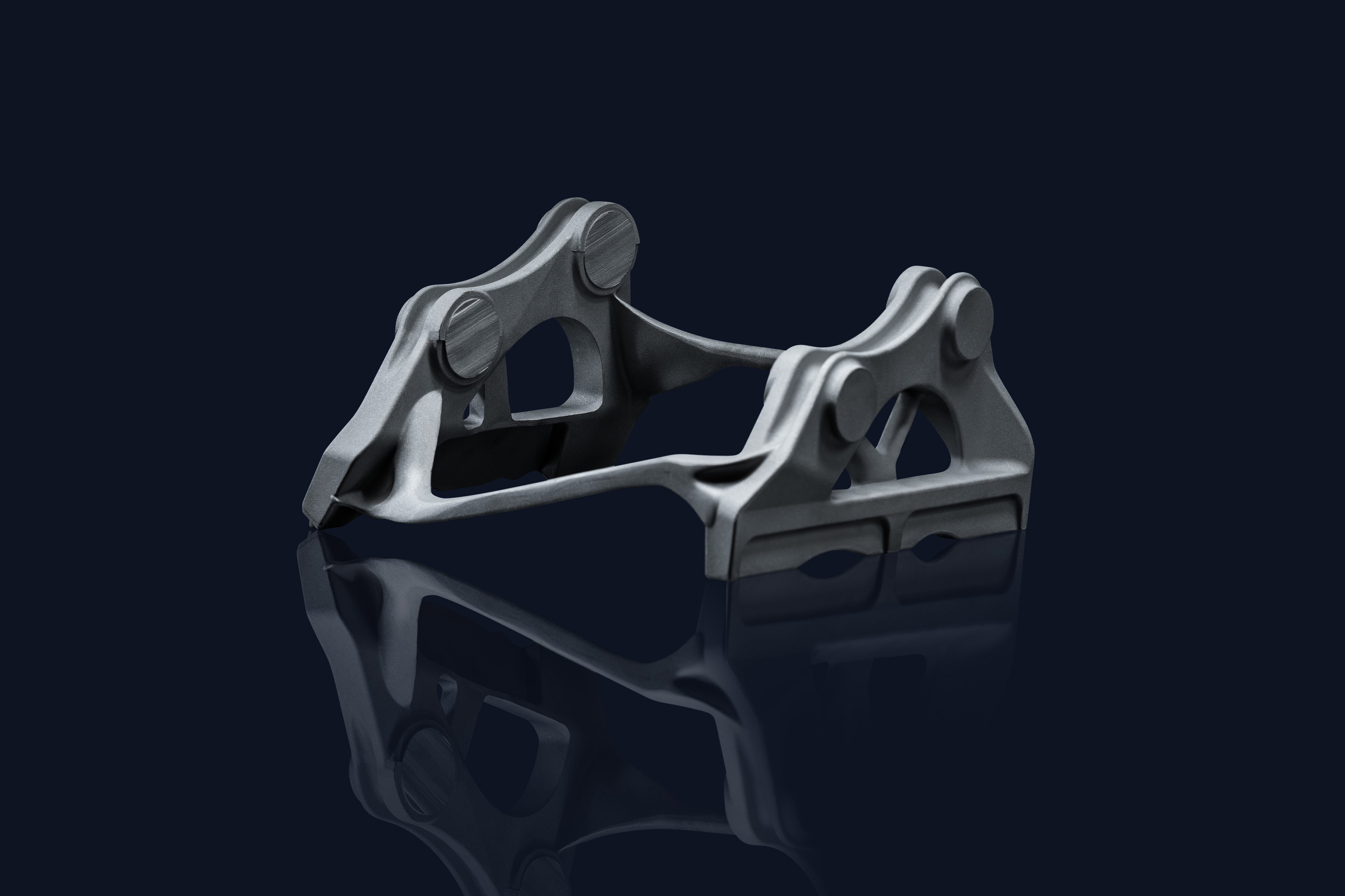

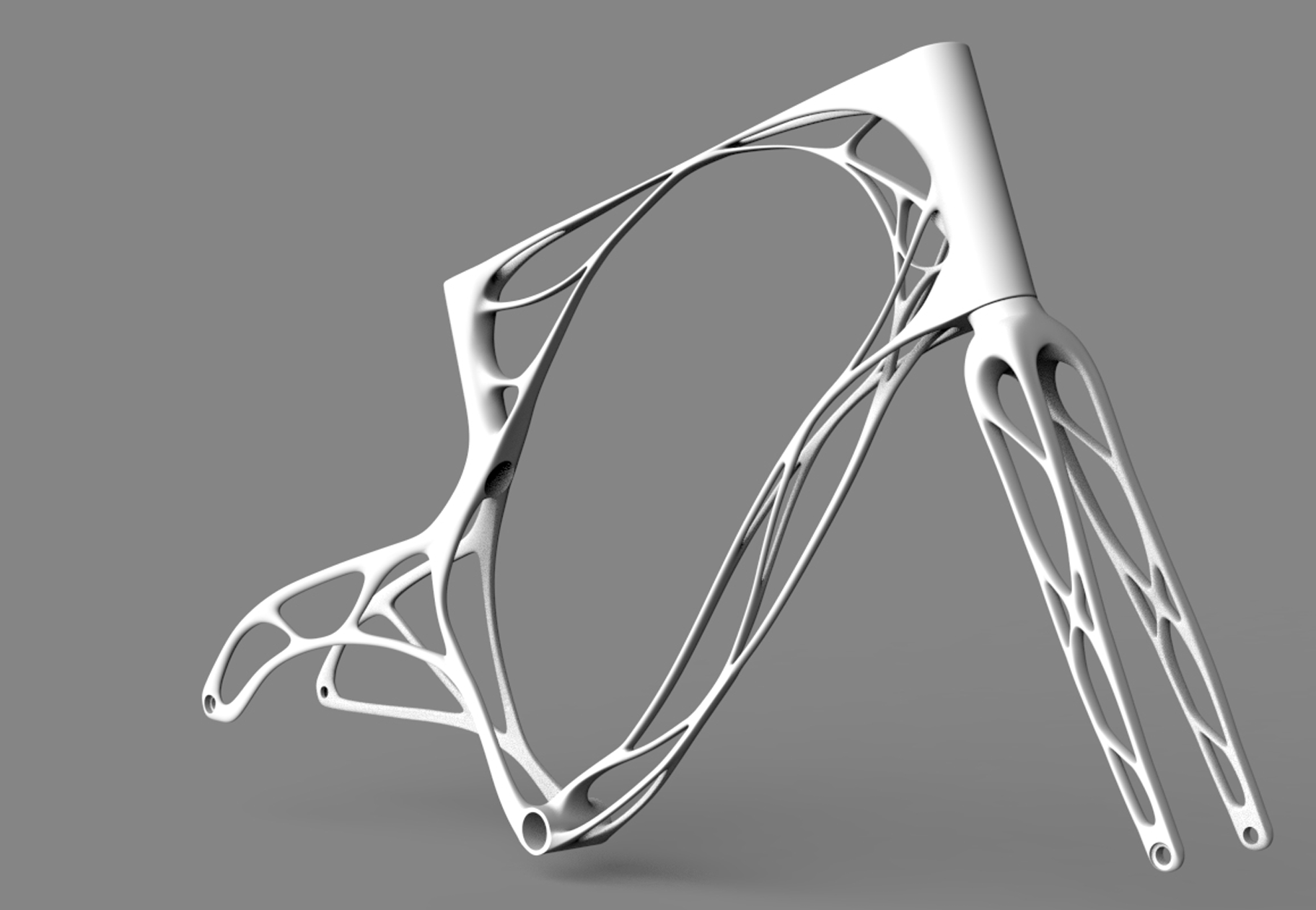

Sarginsons redefines lightweighting through pioneering topological optimization. It transforms casting design via revolutionary digital twin simulations. And it's forging ahead with innovative recycled alloys, advanced heat treatments, state-of-the-art casting software, and enhanced tooling. No facet of casting technology escapes Sarginsons' relentless reinvention for optimal results.

No other aluminium foundry comes close