Sarginsons Technology Cuts Costs

Thanks to the huge number of variables, casting is the most complex of all manufacturing disciplines. Without understanding each nuance, each discipline and the relationships between them it is difficult to minimise production costs, without compromising performance.

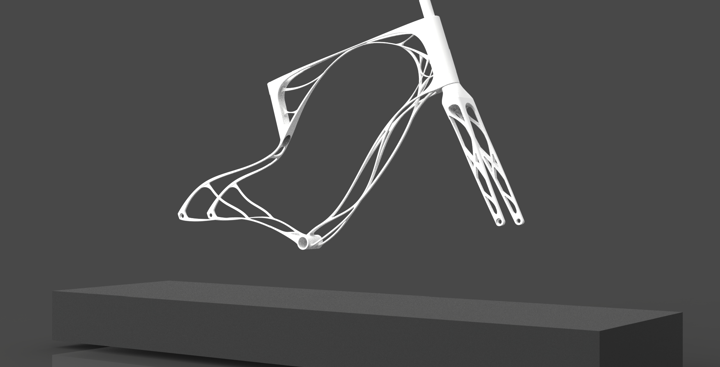

Sarginsons DfM+ considers every aspect of component development from alloy selection, design, solidification, and simulation through to CNC machining, heat treatment and robotic handling: every single step and process is considered. The Sarginsons Technology Centre was developed with this in mind and it's focus is on developing technology that cuts casting costs.

It’s axiomatic that simple design is the best design, but simplification demands true understanding, which has to be earned through research, mistakes and investment. All of which Sarginsons has experienced, suffered and spent over many years.