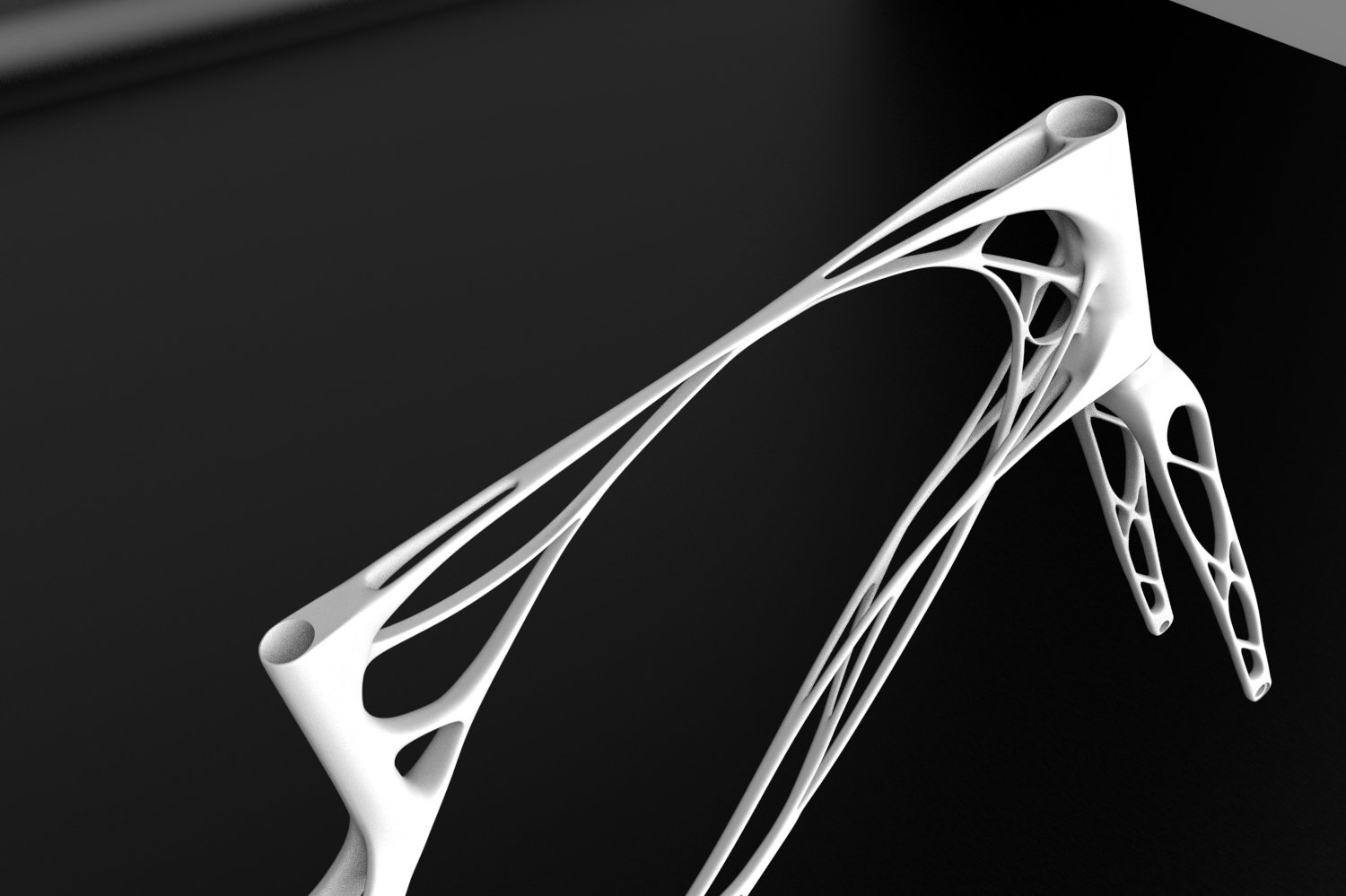

30%+ Mass Reduction. Everytime

Lightweighting castings is a never ending challenge, but it's a problem to which Sarginsons unique range of skills, technology, and experience is well adapted. And this is why Sarginsons has manged to reduce the mass of every casting it has reviewed, by more than 30%, with no loss of mechanical performance.

Perfect lightweighting requires the whole casting package. And it's a big complex, evolving package; involving hundreds, if not thousands, of variables where perfection can ironically rely on exploiting the nature of imperfection. Sarginsons rely on their world leading digital twin simulations and topological optimisation to lead a whole host of other technologies, that together achieve remarkable performance improvements.

You don't just lightweight a casting. You have to live and breathe it. It's research, art, experience and intuition tightly woven into one, controlled package.