One-Piece Castings are Smarter

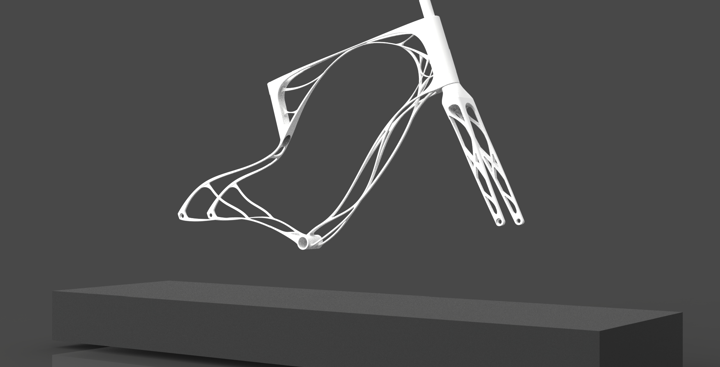

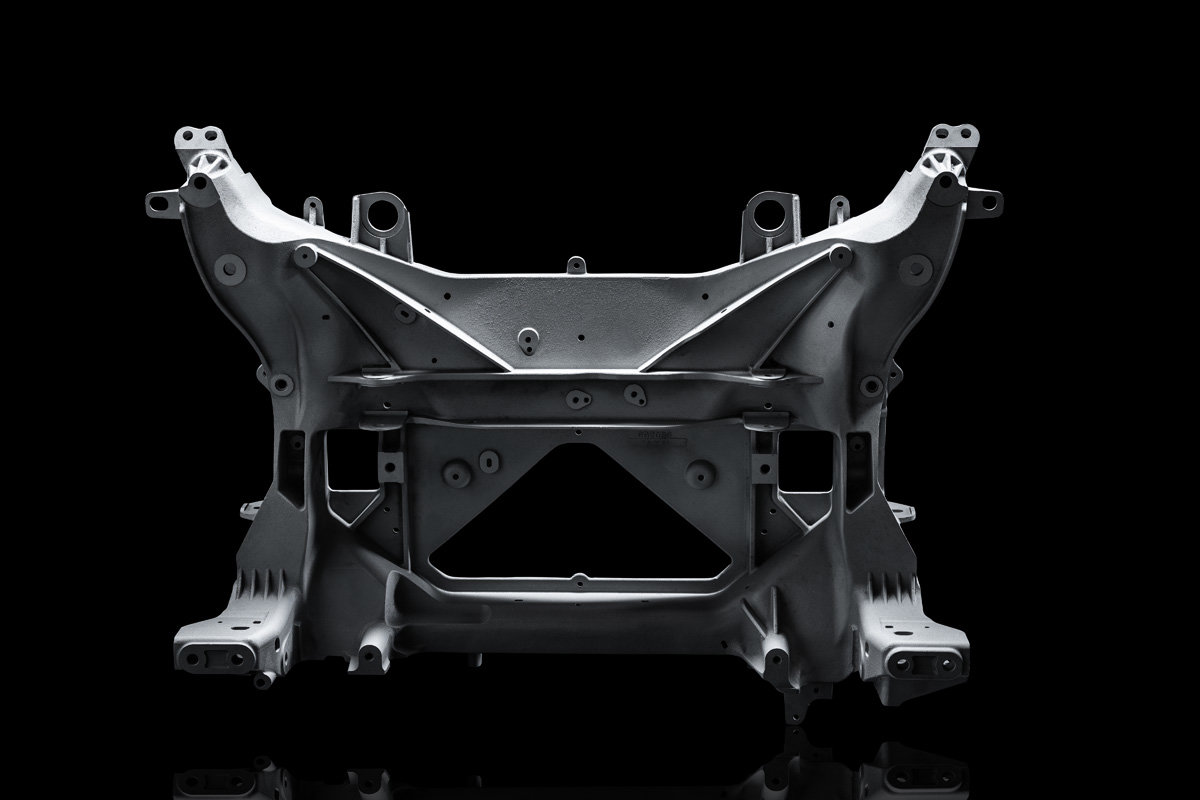

The economies from merging multiple components into one casting are huge, but maintaining mechanical performance, whilst keeping weight down, makes the engineering complex and the outcomes uncertain. Sarginsons has developed a range of unique technologies to facilitate one piece castings, and has designed and produced many, larger, complex castings as a result.

Large cast components complicate mechanical requirements significantly, as more stress, across a larger form, force a geometric increase in intricacy. Sarginsons accommodates these increased difficulties by simulating these stresses and manipulating material microstructures to achieve required mechanical performance.

With a host of unique technologies Sarginsons can better access the economies of merged components than any other company.