Digital Twins Supercharge Design

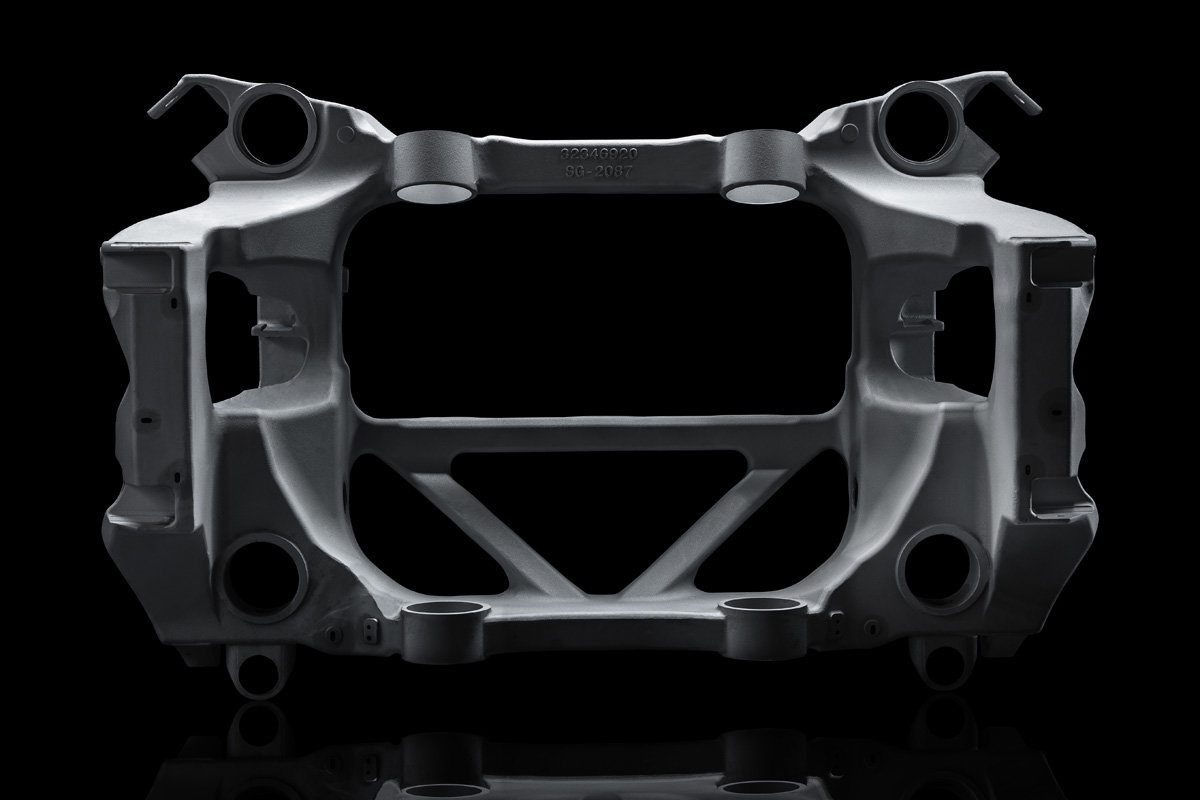

Designing castings is different from any other process. The huge number of variables that affect a casting's performance, and the inability to accurately simulate mechanical characteristics, mean castings are usually poorly designed relative to their mechanical performance.

Sarginsons has totally changed this dynamic with its Digital Twin Simulations technology; the first time globally that the TYE, stress and fatigue performance of casting can be accurately calculated at any point on a component.

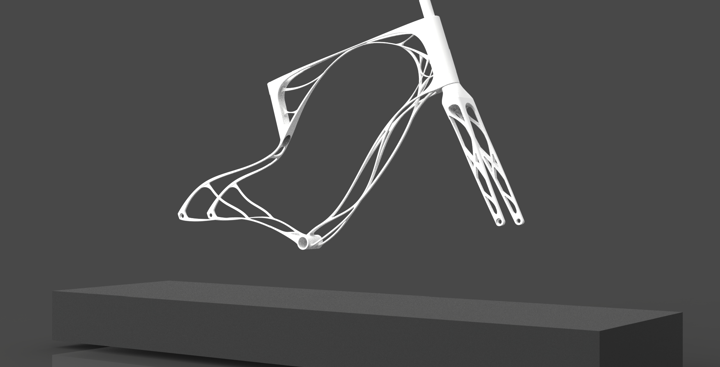

This single step has opened the door to massive lightweighting opportunities, particularly through Topological Optimisation, enhanced design possibilities and the potential, finally, to make casting prototypes that precisely mimic the TYE performance of production castings.