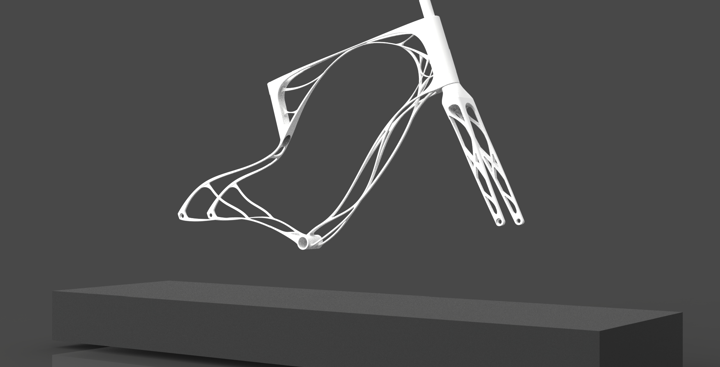

A Unique Cross Member Prototype

Casting prototypes are made using different manufacturing techniques from those in production, usually Sand, and so have different mechanical characteristics from the production components they mimic. They look the same, but mechanical differences, particularly in TYE, means significant additional development may have to occur to industrialise any component.

For this cross member, Sarginsons developed techniques that gave the same mechanical performance to the sand cast component as the gravity cast production component, allowing for a rapid and smooth industrialisation. Everything was right first time. Crucially, as this superior component performance frees designers from concerns about industrialisation, they design better products.

The same technology can also be used for short run production, such as early ramp up production and bespoke product ranges.