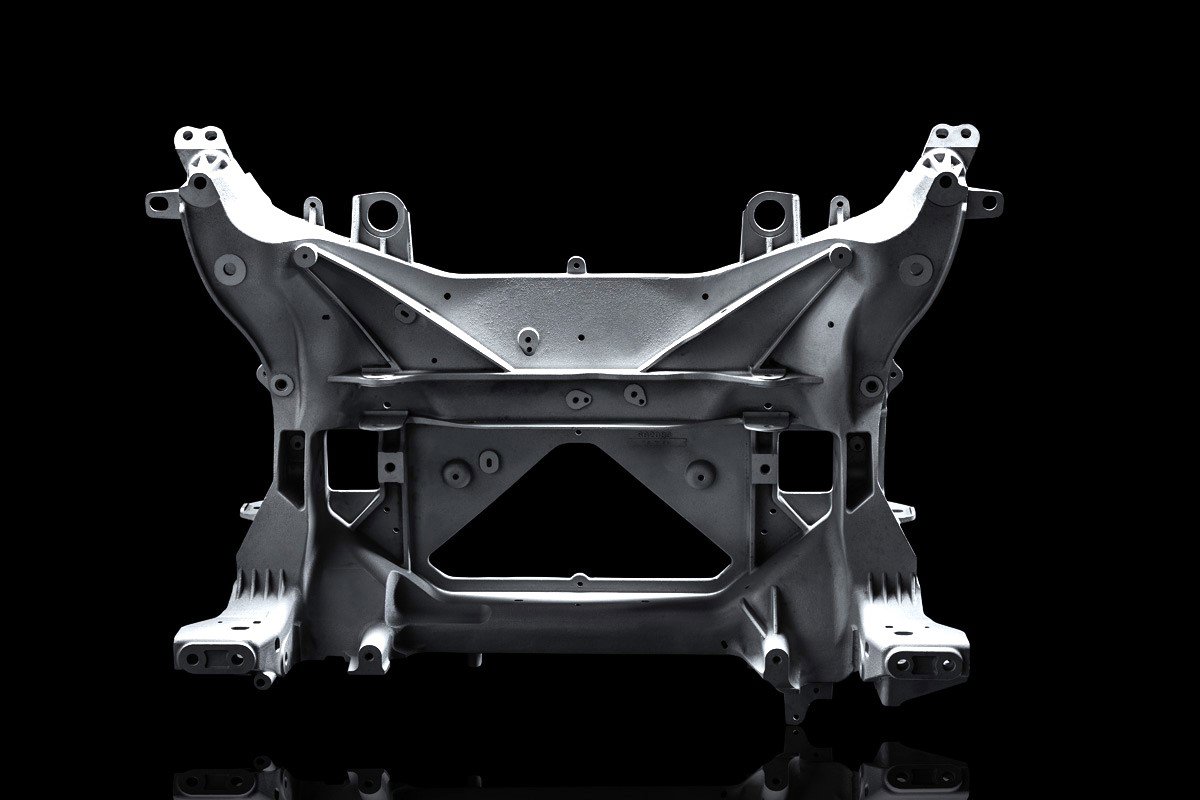

A Complex One Piece Casting

One of the world's largest OEMs required Sarginsons to help improve elongation in a structurally challenging, single piece sub-frame. The work involved some component redesign but it was the use of an innovative cooling solution, to improve TYE in the sand casting, that enabled a production accurate prototype, allowing testing and avoiding expensive complications in production.

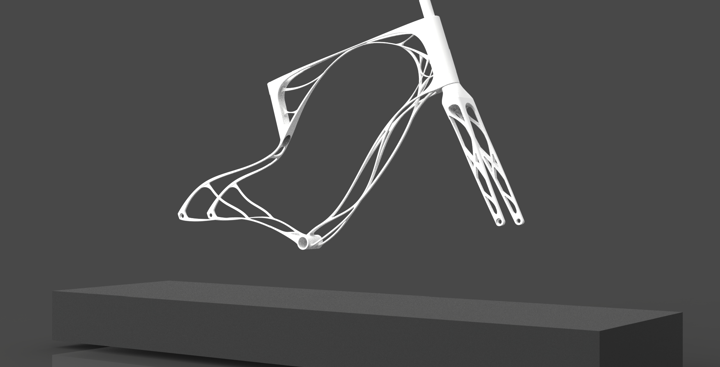

Casting is perfectly suited to combining individual components as it is the most flexible of all manufacturing techniques. This plasticity of design potential has been made real by Sarginsons unique ability to control microstructures and simulate TYE performance in prototypes. With other technological advances Sarginsons is ideally placed to exploit the trend toward incorporating multiple components into one casting.

A one piece casting replacing multiple components makes sense.