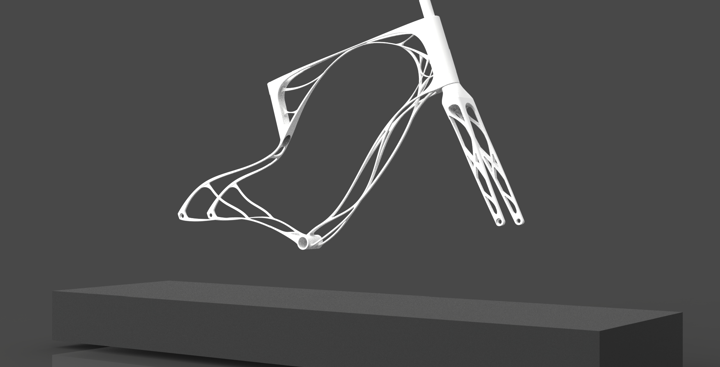

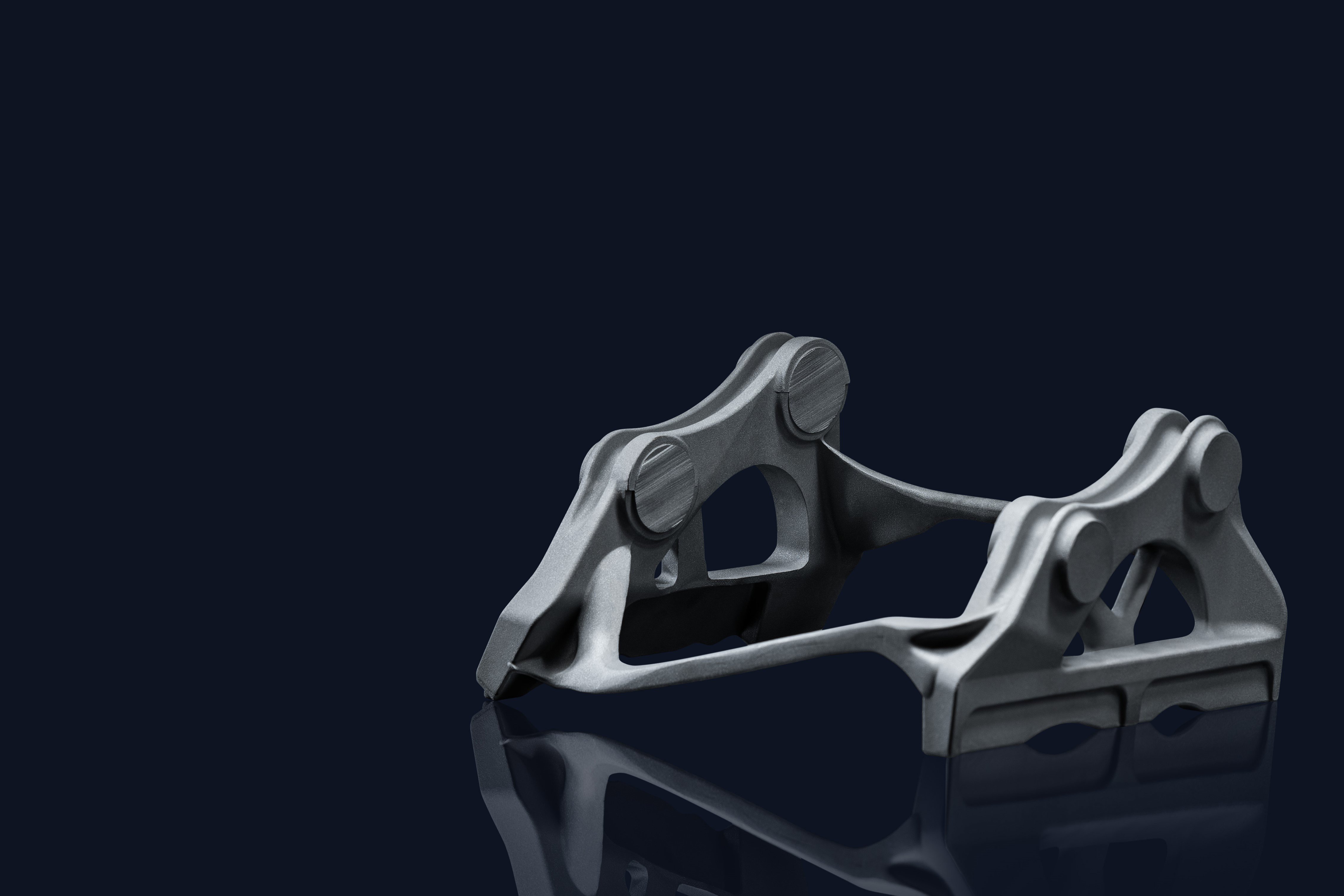

Partially Optimised Wing Roller

Lightweighting is traditionally a balancing act. Take mass out of a component and other desirable characteristics are reduced, particularly strength. Optimised Topology changes this dynamic. It can reduce the mass of a component, by 20% to 40%, whilst improving it's mechanical performance. Less becomes more.

Although being only partially optimised, this Wing Roller achieved a dramatic improvement in performance, despite being previously considered un-castable. This study, performed with a number of aerospace companies and Aerospace Technology Institute, proved that traditional casting, particularly with improvements introduced by Sarginsons, is more than capable of meeting aerospace safety standards.

Traditional casting is massively underused in aerospace but represents goldmine of efficiencies and performance improvements.