24hrs: An Impossible Goal?

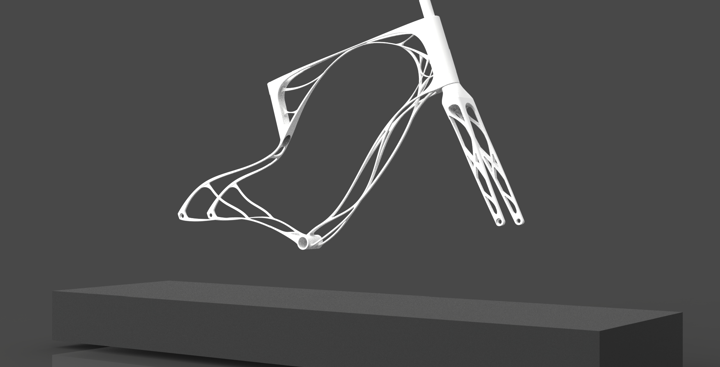

Casting is the most complex of all manufacturing processes. This complexity is often the culprit for delays and cost over runs in product development, as design ambition runs headlong into the realities of physics; particularly when mechanical strength is an issue. This has often raised the question, how fast can you produce a production ready casting from its model?

With a Digital Twin Simulation to prove TYE mechanical performance and a big 3D sand mould and core printer, it is more than possible to produce production ready, mechanically strong components within 24 hours. Whilst 24 hours is probably not required, it does demonstrate the enormous flexibility of Sarginsons casting prowess and its unrivalled ability to solve casting problems quickly, particularly catching up with development timelines.

Digital Simulations shorten development timelines by enabling virtual testing, permitting Sarginsons to deliver a rapid response protocol that aims to cast components from finalised designs in a day.